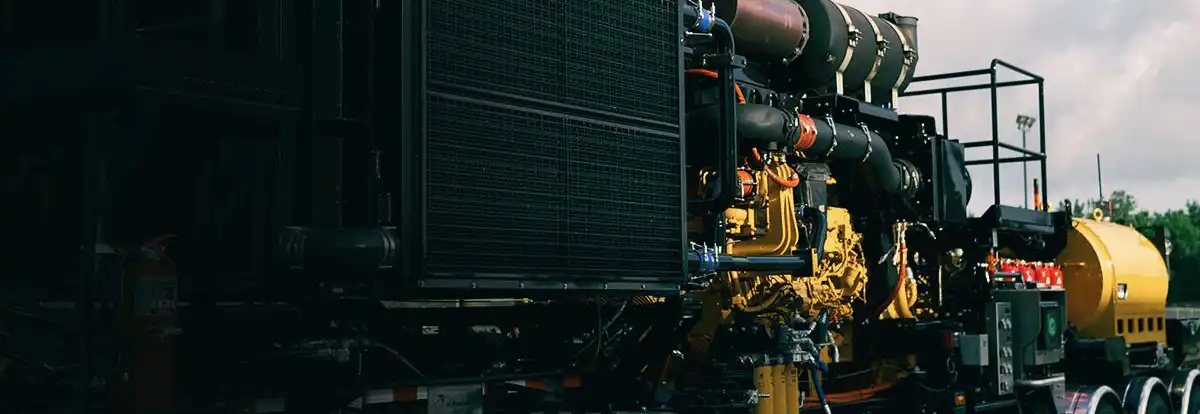

Cat C32 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C32 ACERT engines to deliver excellent performance with low operating costs and emissions. Equipment powered by C32 ACERT engines include well stimulation pumping, pump skids, nitrogen units, acidizing units, blenders, and hydraulic power units. Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. Cat C32 ACERT Industrial Diesel Engine. Ratings: 597-1119 bkW (800-1500 bhp) @ 1800-2100 rpm meet U.S. EPA Tier 2 equivalent and China Stage III emission standards. They are available using U.S. EPA Flexibility, and for other regulated and non-regulated areas.

Maximum Rating 1007 BHP

Emissions EPA and CARB Non-Road Mobile Tier 2, IMO Tier II, China Stage III

Displacement 1960.5 in³

Length 76.18 in

Aspiration Turbocharged - Aftercooled

Bore 5.7in

Displacement 1960.5in³

Flywheel Teeth 136

Flywheel and Flywheel Housing SAE No. 0 or SAE No. 1

Governor and Protection ADEM A3

Maximum Rating 1007BHP

Rotation from Flywheel End Counterclockwise

Stroke 6.4in

Emissions EPA and CARB Non-Road Mobile Tier 2, IMO Tier II, China Stage III

Height 54.66in

Length 76.18in

Weight 5040lb

Width 56.34in

Cooling System 14.5gal (US)

Connections configured for ATAAC (Air-to-Air-Aftercooled) or remote heat exchanger

ADEM A4 electronic control module

Electronic governing, PTO speed control

Customer programmable ratings

Cold mode start strategy

Automatic altitude compensation

Automatic fuel temperature compensation

Programmable low and high idle, and top engine speed limit

Electronic diagnostics and fault logging

Engine monitoring system

SAE J1939 broadcast (diagnostic and engine status)

Gear-driven centrifugal jacket water pump — RH

Integrated thermostat and housing

Engine oil cooler

Optional installed transmission oil cooler

Exhaust manifold — dry

Two vertical exhaust outlets (front and rear)

MEUI

Fuel priming pump

Fuel transfer pump

Primary and secondary fuel filter — RH configured for remote mounting (installed RH on shipping plate)

SAE No. 0 or SAE No. 1 flywheel iron housing

SAE No. 0 or SAE No. 1 flywheel

Optional transmission adapter

Crankcase breather

Oil filter — RH standard, optional LH or remote mount service

Oil level gauge — RH standard, optional LH or dual service

Oil filler — RH standard, optional LH or dual service

Shallow oil pan, rear sump

Trunnion front support

Vertical and horizontal pads on rear flywheel housing

24V electronic

Engine overspeed with optional air shut-offs with indicators

Low engine oil pressure

Fuel filter restriction

Fuel temperature

High engine coolant temperature

Low engine coolant temperature

Vibration damper and optional guard

Lifting eyes

Optional customer wiring connector

Service tool connector

Paint — Cat yellow

Air cleaner

Air inlet adapters

Turbocharger outlet adapters

Air lines

Battery chargers

Charging alternators

Alternator mounting

Circuit breakers and mountings

Dry charge coolant conditioners

Thermostat housing

Coolant level sensor

Radiator

Blower fans

Suction fans

Fan adapters

Fan drives

IMO certifications

Elbows

Mufflers

Electric fuel priming pump

Customer management device

Interconnect harness

Gauges and instrument panels

Oil pans

Oil service side

Oil level gauge

Oil filters

Lubricating oils

Structural steel base

Engine support — front

Engine support — rear

Auxiliary drive

Damper pulley

Hydraulics gear pumps

Mechanical shutoffs

Solenoid shutoffs

Electric starting motors - 12V, 24V

Battery sets - 24V

Battery cable

Battery rack

Starting aids

Transmissions water lines

Transmissions cooler