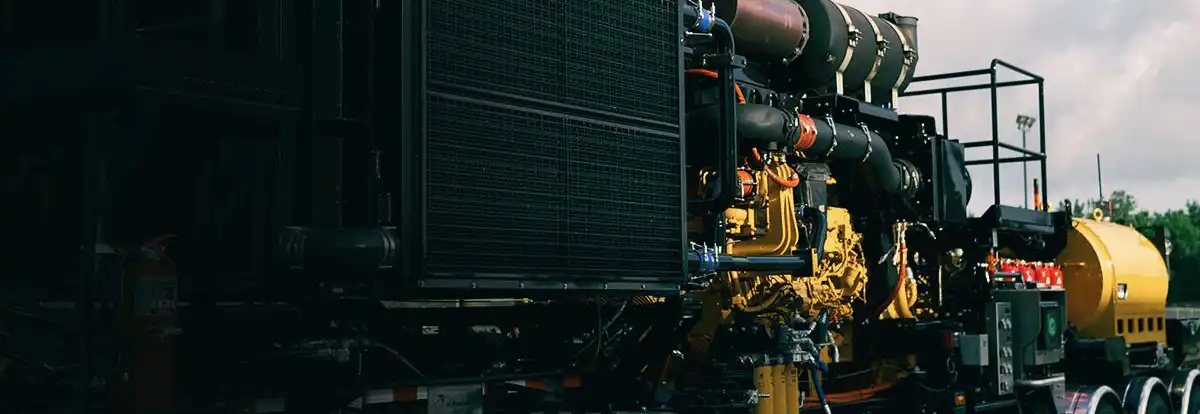

Well stimulation operations in the oilfield are complex and demanding. The 3512C (HD) with dynamic gas blending engine for well stimulation operations was specifically developed to lower fuel cost while while meeting the highest standards in performance, durability, reliability, and emissions. Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. 3512C (HD) engines, with ratings: 1678-1864 bkW (2250-2500 bhp) @ 1900 rpm meet IMO Tier II, U.S. EPA Marine Tier 2, and U.S. EPA Non-road Tier 2 equivalent emission standards. They are available using U.S. EPA and EU Flexibility, and for other regulated and non-regulated areas.

Maximum Rating 2500 BHP

Emissions Non-current EPA Tier 2

Displacement 3574 in³

Minimum Rating 2150 BHP

Aspiration Turbocharged-Aftercooled

Bore 6.7in

Displacement 3574in³

Flywheel Teeth 151

Flywheel and Flywheel Housing SAE No. 0

Maximum Rating 2500BHP

Minimum Rating 2150BHP

Stroke 8.5in

Emissions Non-current EPA Tier 2

Height 86.3in

Length 110.4in

Weight 14650lb

Width 59.2in

Air-to-air aftercooled (ATAAC) (512DW04, 512DW05, 512DW06, 512DW07)

Air cleaners (single element w/service indicator)

ADEM A3 ECU, LH

With electronic fuel injector fuel system (10 amp DC power required to drive electronic engine control module)

ATAAC (512DW04, 512DW05, 512DW06, 512DW07)

Torque converter connections

Thermostats and housing, jacket water pump, gear-driven centrifugal (gear-driven centrifugal pumps)

Connections for radiator cooling

Dual outlets: 88.9 mm O.D. (3.5 in) elbow hose connections

Land Well Service Engine:

Offshore Well Service Engine:

Flywheel, SAE No. 0, 151 teeth

Flywheel housing, SAE No. 0

Primary fuel filter

Fuel priming pump

Fuel filter, RH spin-on type

Fuel transfer pump

Electronically controlled unit injectors

No standard instrumentation

Optional — remote instrumentation available Service meter

Crankcase breather — top-mounted

Oil cooler

Oil filler and dipstick — RH

Oil pump

Oil filter — RH spin-on type

Rear sump oil pan, 250-hour change interval

Oil pan drain valve, 3/4" NPT female connection

Fumes disposal

Scavenger pump

Trunion front support

ATAAC (512DW04, 512DW05, 512DW06, 512DW07)

Front housing, two-sided

ADEM A3 ECU system to provide customer programmable engine deration strategies to protect against adverse operating conditions

Emergency stop logic inputs provided at 40-pin customer interface connection

ATAAC (512DW04, 512DW05, 512DW06, 512DW07)

Single Air inlet shutoff

Paint, Cat yellow

Vibration damper and guard

Lifting eyes

Air cleaner

Remote air inlet adapters

Air inlet heater

Battery chargers

Charging alternators

Throttle position sensors

Coolant level sensor

Coolant conditioner

Connections

IMO Certification and European Union Certification

Flexible exhaust fitting

Elbows

Flange

Flange and exhaust adapters

Manifold

Mufflers

Flexible fuel lines

Fuel cooler

Fuel priming pumps

Water/fuel separator

Fuel level switch

Engine mount premium panel

Remote instrumentation

RH oil filters

Oil pan accessories

Oil pan front sump — 250 hrs

High capacity oil pan — 500 hrs

Front Accessory Drives

Auxiliary Drive Shaft

Auxiliary Drive Pulleys

Front Stub Shaft

Front Crankshaft Adapter

Pulleys

Corrosion Protection

Air starting motors

Air pressure regulator

Air silencer

Hydraulic starter

Battery sets— 24V

Battery cable