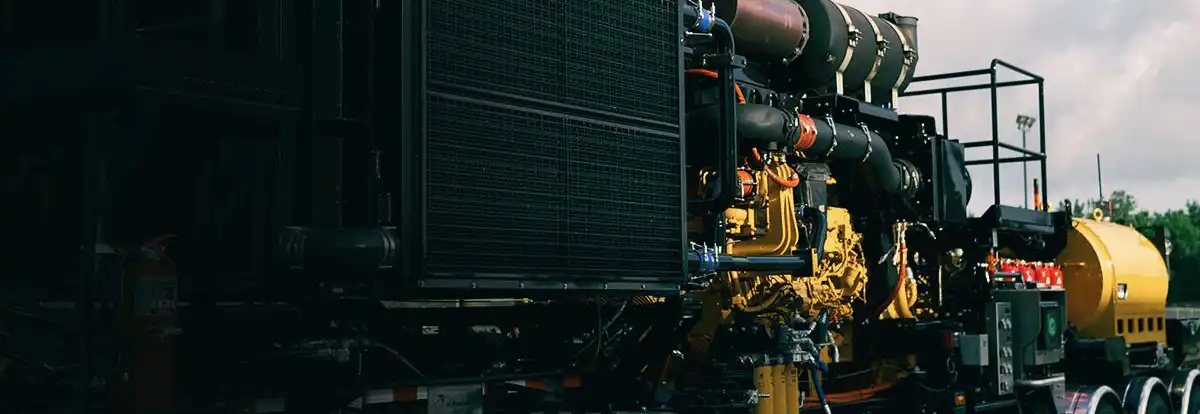

Cat C7 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C7 ACERT engines to deliver excellent performance with low operating costs and emissions. Applications powered by C7 ACERT engines include pump skids, acidizing units, cementing units, coil tubing units, and hydraulic power units. Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. C7 ACERT engines, with ratings: 153 - 224 bkW (205 - 300 bhp) @ 2200 rpm meet IMO Tier II, U.S. EPA Marine Tier 3, EPA Non-road Tier 3 equivalent and EU Stage IIIA equivalent emission standards. They are available using U.S. EPA and EU Flexibility, and for other regulated and non-regulated areas.

Maximum Rating 275 BHP

Emissions EPA & CARB Non-Road Tier 3, EU Stage IIIA, EPA Marine Tier 2, IMO Tier II

Displacement 442 in³

Minimum Rating 205 BHP

Aspiration Turbocharged-Aftercooled

Bore 4.3in

Displacement 442in³

Flywheel Teeth 156 (SAE 1), 134 (SAE 2), 126 (SAE 3)

Flywheel and Flywheel Housing SAE 1, 2, or 3

Governor and Protection Electronic (ADEM™ A4)

Maximum Rating 275BHP

Minimum Rating 205BHP

RPM 2200r/min

Rotation from Flywheel End Counterclockwise

Stroke 5in

Emissions EPA & CARB Non-Road Tier 3, EU Stage IIIA, EPA Marine Tier 2, IMO Tier II

Height 40.6in

Length 41.5in

Weight 1386lb

Width 29.8in

Lube Oil System - Refill 4.8gal (US)

Turbocharger, separate circuit (SCAC)

Single, right-side, center-mounted turbo with water-cooled turbine housing

Air inlet, RH side, rear facing, 101.6 mm (4 in.) connection type

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation

Fuel cooled ECU

Power compensation for fuel temperature

Programmable low and high idle

Electronic diagnostics and fault logging

Programmable monitoring system (engine speed, temperature, pressure)

J1939 broadcast (diagnostic and engine status)

Certified electrical control system

Derated engine: automatic ambient temperature compensation

Thermostats and housing, front-facing outlet — 51 mm (2.01 in) connection

Jacket water pump — belt-driven, centrifugal

Water pump — inlet RH front vertical inlet (pointing down) — 63 mm (2.48 in)

Single, right-side, center-mounted turbo with water-cooled turbine housing

Exhaust manifold — water-cooled

Front turbo exhaust

Mandatory selection of: SAE No. 1, SAE No. 2, or SAE No. 3 flywheel and housing SAE standard rotation

HEUI fuel system

Fuel filter — secondary, LH front (2-micron high performance)

Fuel transfer pump — left front

Fuel priming pump — left front

Crankcase breather — top rear

Crankcase fumes disposal — RH

Oil cooler — RH

Oil filter — RH

Oil pan — front sump, 31 L (33 qt) oil change capacity

Oil filler — front top valve cover

Oil level gauge — LH rear

Engine oil pump — gear-driven

Oil valve sampling, RH

Crankshaft drive pulley — 2 grooves, 190 mm (7.5 in) diameter, 22.3 mm (0.88 in) wide

Vibration damper

Lifting eyes

Literature

No paint

Flywheel housing and flywheel

Primary filter/water separator

Turbo orientation

Precleaner

Air Inlet elbow

Water outlet elbow

Coolant conditioner

IMO certification

Crankshaft seal

Gauges and instrument panels

Oil pans

Drain and cover

Remote oil filters

Lubricating oils

Structural steel base

Engine support -- front and rear

Crankshaft pulleys

Tool set