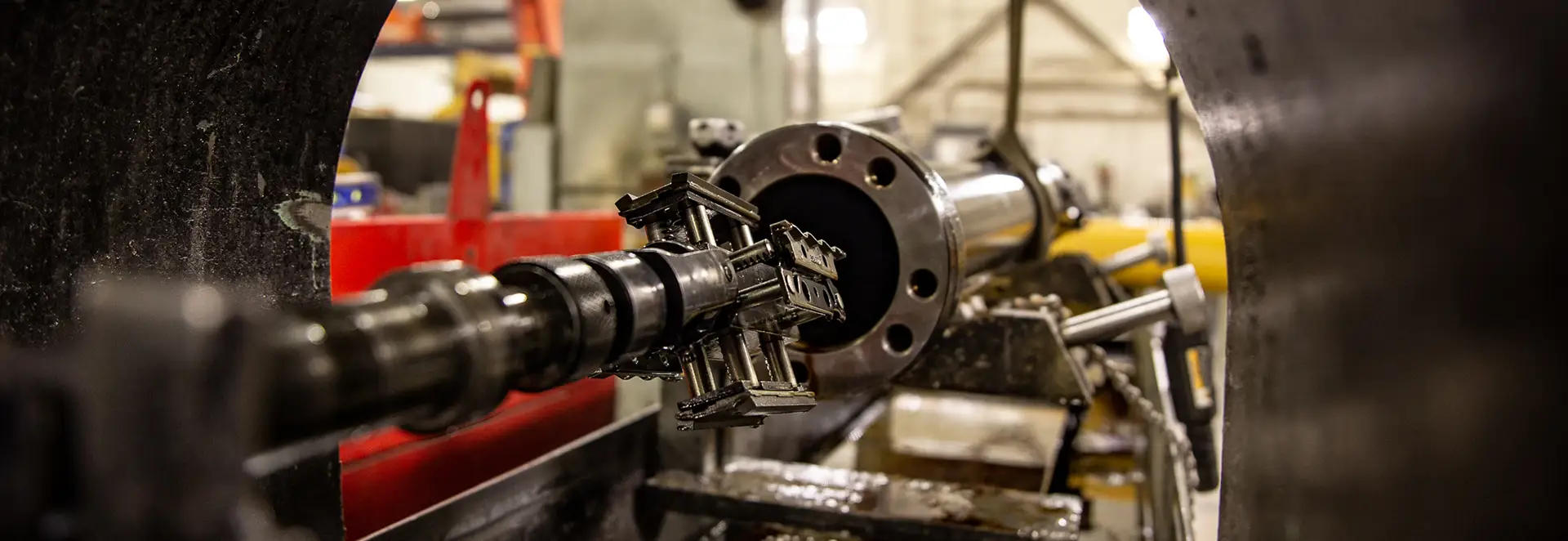

Cat® Certified Component Rebuilds

Cat® products have a well-deserved reputation for reliable, long-lasting performance under the most challenging job site conditions. But even a rugged, durable Cat machine will eventually need upgraded parts and components to keep it functioning at a high level and maximize its life span.

A Cat Certified Machine Component Rebuild by Wheeler Machinery Co. can provide a cost-effective solution for replacing old, worn-out or damaged engines, transmissions and power trains. We help construction companies and other businesses throughout Utah and parts of Wyoming and Nevada get the most out of their heavy equipment and meet their project objectives.

What Are Component Rebuilds?

Heavy equipment component rebuilds entail a complete reconditioning of the parts. The result will be a totally refurbished product that looks and performs like new. All work must comply with the stringent certification guidelines developed by Caterpillar to ensure the components meet the highest performance, quality and reliability standards.

Cat Component Rebuild Process Steps

Rebuilding Cat components consists of the following steps:

- Inspection: Our technicians will conduct a visual inspection and review the machine’s service history. We’ll also perform an analysis of the oil, coolant and fuel.

- Disassembly: We’ll take the component apart to determine whether the individual parts can be reused or require replacing.

- Reconditioning: We’ll recondition all reusable parts to ensure they meet the Cat certification specifications.

- Engineering updates: Our techs will apply any engineering updates released by Caterpillar since the component’s initial development to provide the most efficient performance.

- Reassembly: We’ll reassemble the part and perform a series of quality checks.

- Testing: Our techs will conduct multiple tests to ensure the newly reassembled component will deliver the results you expect.

- Repainting: Once we’ve verified that the rebuilt component is as good as new, we’ll apply the finishing touches like repainting and adding decals and identification plates.

- Installation and inspection: We’ll install the reconditioned component and test the support systems to verify everything is functioning correctly.

- Customer evaluation: You’ll have the opportunity to review the work by testing the machine with the rebuilt component in your typical job site environment.

Why Choose Us for Your Component Rebuild Project?

Wheeler Machinery Co. operates a full-service component rebuild center that includes state-of-the-art equipment, tools and technology. Our well-trained, highly skilled technicians can complete your project quickly and efficiently, enabling you to get your machine back on the job with minimal delays.

We can customize your component to meet your performance specifications. Customization also makes it easier to reinstall and connect the upgraded part compared to purchasing an off-the-shelf product.

Our Cat component rebuilds come with comprehensive warranties, giving you extra protection and peace of mind. A one-year, 5,000-hour warranty is standard, but you can also upgrade to an extended plan featuring four years and 8,000 hours.