Rebuild. Restore. Reinvest in Your Equipment.

Cat® Certified Equipment Rebuilds give your equipment a second life at a fraction of the cost of buying new. Keep your machines running at peak performance while saving money and avoiding downtime.

- Save up to 60% compared to new equipment costs

- Restore 100% performance and productivity

- Extend your machine’s life by thousands of hours

- Reduce unexpected downtime with proactive rebuilds

Why Rebuild Your Equipment?

Don’t let hidden wear and tear slow you down. Your equipment can lose up to 20% efficiency before you even notice, resulting in one lost day of production every week. This loss impacts your bottom line—missed deadlines, reduced output, and higher operating costs.

A Cat® Certified Rebuild restores your machine’s performance, preventing costly downtime and keeping your business moving forward. Stay productive and get the most out of your equipment by addressing wear before it becomes a problem.

Give your machine a second life for maximum value.

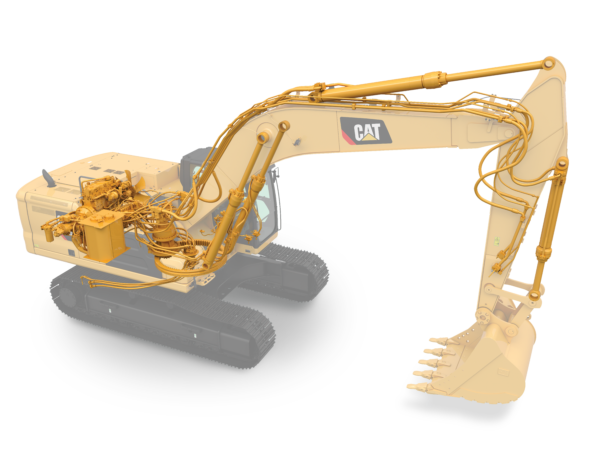

CAT® CERTIFIED MACHINE REBUILDS

One of the many benefits of owning and using Cat equipment is its extended life span. Cat products can deliver peak performance and withstand the rigors of heavy use over many years, providing an excellent return on investment.

If you have an older Cat machine in Utah or portions of Nevada or Wyoming that’s finally showing signs of slowing down, there’s an affordable way to give it a second life. Wheeler Machinery Co. can perform a Cat Certified Rebuild that will restore the equipment to like-new condition.

Flexible Options to Maximize Equipment Life and Return on Investment.

Certified Rebuild The entire machine

Certified Power Train The full power train

Certified Hydraulic Rebuild An excavator’s hydraulic system

Certified Machine Component Rebuild Engines and/or transmission/torque converter combinations

Certified Engine Rebuild Generator sets, pumps, and other power applications

WHAT IS A CAT CERTIFIED REBUILD?

Caterpillar introduced the Cat Certified Rebuild Program in the 1980s to give equipment owners a cost-effective alternative to purchasing brand-new models. The program empowers Cat dealers to recondition older machines by replacing old or worn-out parts and components and making other significant upgrades.

Caterpillar implements strict standards that dealers must adhere to before it issues the certification. The dealer receives a list of parts that require inspecting or replacing. It also gets recommendations regarding machine enhancements and engineering updates that expand the product’s original capabilities, which can often make it better than new.

All rebuilds consist of a comprehensive step-by-step methodology to meet the certification requirements:

- Initial inspection

- Disassembly

- Reconditioning

- Application of engineering updates

- Power train testing

- Reassembly

- Performance testing

- Repainting

- Serial or product identification number assignment

- Final customer evaluation

In addition to performing complete machine rebuilds, Wheeler Machinery Co. offers engine, transmission and power train rebuild packages.

Giving your Cat machines a second life can offer numerous benefits for your business:

- Substantial cost savings: Updating older equipment helps you save thousands of dollars compared to buying a brand-new model.

- Enhanced performance: The addition of new Cat parts and components and engineering updates can significantly improve your machine’s productivity and efficiency at the job site.

- Emissions compliance: A Cat Certified Rebuild can ensure your equipment meets increasingly stringent emissions guidelines.

- Improved reliability: As heavy equipment ages, the risk of experiencing mechanical issues increases. Replacing worn or outdated parts reduces the likelihood of an unexpected breakdown.

- Increased comfort and control: Heavy equipment rebuilds with cab enhancements can make your machine operators more comfortable and productive and offer access to the latest user technologies.

- Warranty coverage: A Cat Certified Rebuild and a Cat Certified Power Train Rebuild comes with extended warranty coverage for your protection and peace of mind.

As the region’s exclusive Cat equipment dealer, you can trust Wheeler Machinery Co. to execute a flawless Cat Certified Equipment Rebuild project. Our well-trained, experienced technicians will ensure the work meets your requirements. We’ll also be here to keep your rebuilt machine on the job with preventative maintenance and repair services.

Track-Type Tractors (Dozers)

- Small Dozers:

- D1

- D3

- D5

- Medium Dozers:

- D6

- D7

- D8

- Large Dozers:

- D9

- D10

- D11

Hydraulic Excavators

- Small Excavators:

- 313

- 315

- 317

- Medium Excavators:

- 320

- 323

- 330

- Large Excavators:

- 336

- 349

- 390

Wheel Loaders

- Small Wheel Loaders:

- 926M

- 930M

- 938M

- Medium Wheel Loaders:

- 950M

- 962M

- 966M

- Large Wheel Loaders:

- 980M

- 982M

- 988K

Motor Graders

- 120

- 140

- 160

Articulated Trucks

- 725

- 730

- 745

Backhoe Loaders

- 415F2

- 420F2

- 430F2

Skid Steer Loaders

- 226D3

- 232D3

- 242D3

Track Loaders

- 953K

- 963K

- 973K

Compactors

- Soil Compactors:

- CS44B

- CS56B

- CS68B

- Pneumatic Rollers:

- CW34

Pipelayers

- PL61

- PL72

- PL83

Scrapers

- 613K

- 627K

- 657G

Off-Highway Trucks

- 770G

- 772G

- 773G

Telehandlers

- TH255C

- TH3510D

- TH514D

Cold Planers

- PM310

- PM620

- PM822

Wheel Excavators

- M314F

- M316F

- M322F

Multi Terrain Loaders

- 239D3

- 249D3

- 259D3

Material Handlers

- MH3022

- MH3024

- MH3026

Underground Mining Loaders

- R1300G

- R1600H

- R1700G

Hydraulic Mining Shovels

- 6015B

- 6020B

- 6030

Asphalt Pavers

- AP355F

- AP555F

- AP655F