Cat Hydraulic Excavator Undercarriage

We offer more Cat undercarriage parts and options than any other manufacturer because we know that the more precisely you match iron to application, the more effective and efficient your work will be—and that builds a stronger bottom line.

Cat Excavator Undercarriage and Wear Life Assurance Programs

Our Cat Excavator Undercarriage Assurance Programs cover all major moving undercarriage components on Cat Track-Type Tractors, Track-Type Loaders and Track-Type Hydraulic Excavators.

Custom Track Service (CTS) for Caterpillar Excavator Undercarriages

When Cat excavator undercarriage are improperly managed it can account for more than 50% of machine maintenance costs. That’s why we provide Custom Track Service (CTS) for managing your Caterpillar excavator undercarriage system.

CTS allows us to accurately monitor Caterpillar excavator undercarriage performance and predict wear rates. That means you can more effectively evaluate service options, plan your maintenance and schedule downtime. CTS analysis can be completed on your job site, which helps you make informed decisions to keep your operating costs as low as possible.

Worldwide Cat Excavator Undercarriage Parts Availability

Our industry-standard Cat excavator Undercarriage parts distribution network makes most new parts available to you the same day. In fact, we guarantee parts where you need them within 24 hours to keep you up, running and profitable.

The Right Cat Excavator Undercarriage Parts for Your Needs

Every Cat excavator undercarriage is designed by Caterpillar engineers and built to exacting specifications based on the real-world experience of our customers. So, when you choose a Cat excavator undercarriage, you know it’s not just the right choice, it’s the best choice.

To help decide which Cat excavator undercarriage is the right fit for your work and your machine, ask these questions:

- How long will I own this machine?

- How many hours a week will I be using this machine?

- What are my typical ground/soil conditions?

- What are my impact conditions?

- What attachments are on my hydraulic excavator?

- What are the grades/slopes on my job site?

Precisely defining these parameters will help lead you to the best undercarriage choice for your needs.

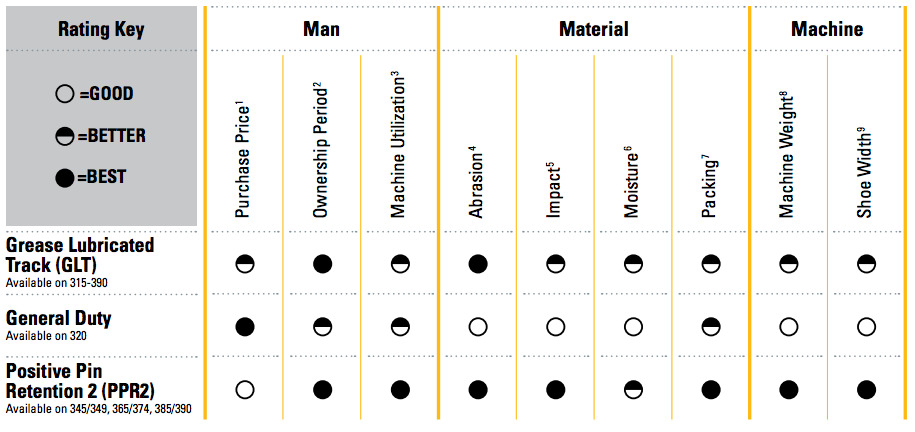

Excavator Undercarriage Selection Guide

Grease Lubricated Track

All current model Cat Excavator undercarriages are equipped with Grease Lubricated Track (GLT). These Tracks maintain the strength of the solid track pin and provide the added benefit of joint lubrication early in the life of the track. However, unlike Sealed and Lubricated Track, the GLT will not provide lubrication for the life of the track.

For as long as the GLT track joint in your Caterpillar excavator undercarriage retains the grease, there will be no internal wear of the bushing and pin. Once the grease lubrication is depleted, internal wear will begin in the same manner as Sealed Track. The length of time that the joints remain lubricated will vary with the Excavator model but generally, the lubricated life will range from 1200 to 2500 hours

The Grease Lubricated Track on your Cat Excavator Undercarriage will:

-

- Improve internal wear life by 25% or more over Sealed Track

- Decrease undercarriage noise

- Allows for enhanced Cat excavator undercarriage management opportunities

Grease is under high pressure.

Grease coming out of the relief valve under pressure can penetrate the body causing injury or death.

Do not watch the relief valve to see if grease is escaping. Watch the track or track adjustment cylinder to see if the track is being loosened

Cat Positive Pin Retention 2 (PP2) Track

Designed for high-impact and high-travel applications such as mining, heavy construction, pipe laying, demolition, and scrap handling. Positive Pin Retention 2 (PPR2) Track is an exclusive Caterpillar undercarriage offering that mechanically locks the link to the pin.

- Resists end-play generation and link movement on the pin

- Tightly controls seal motion for long internal pin/bushing wear life

- Resists fatigue & crack formation with redesigned, stronger track links

PPr2 track features specially machined links, and pins with a radial groove. during assembly, link material is pressed into the groove between the link and pin. this locks the joint with the correct amount of end play.

- Prevents outward movement of the link on the pin

- Keeps end play within the optimum range for sealing

- Contains the grease and excludes the debris for as long as possible

PPr2 is especially recommended for mining, heavy construction, pipe laying, demolition, and scrap handling. any application with high impact and/or travel rates will apply high loading and twisting forces into the track chain, and could benefit from PPr2. Machines equipped with wide or single grouser shoes should also consider PPr2.

Cat General Duty Track

We recommend General Duty Cat Undercarriage track which is also a Grease Lubricated Track (GLT) for your low-to-moderate impact applications where the elevated performance of the Cat Grease Lubricated Undercarriage is not needed.

- While General Duty is built to different specifications than GLT, its design makes General Duty and GLT components interchangeable.

- Cat GLT shoes can be installed on General Duty link assemblies to meet various customer requirements.

General Duty offers a variety of track shoe options. In addition to Cat excavator undercarriage parts and components, track shoe selection can impact traction and rotation as well as overall undercarriage wear life. For the conditions in which General Duty Undercarriage will typically operate, moderate service shoes offer optimal performance and wear life.