TA Inspections for Total Equipment Care

TA Inspections and proactive preventative maintenance are the best way to keep your heavy equipment running properly, avoid unnecessary wear and tear, and maximize uptime. An inspection by our expert technicians helps identify maintenance needs early, ensuring your equipment stays in top condition and providing you with a detailed report to help you make critical business decisions.

Technical Inspection – Level 1 (TA-1)

TA-1 involves a basic visual assessment to detect potential issues before they escalate into major maintenance problems.

During this inspection, we perform:

- Structural Checks: Inspection for visible damage or irregularities.

- Component Inspection: Identification of broken, loose, or missing parts affecting functionality.

- Fluid Analysis: Assessment of fluid levels, colors, and conditions to ensure smooth operation.

- Noise Detection: Identification of unusual noises indicating underlying mechanical issues.

- Leak Inspection: Evaluation of seals and detection of potential fluid leaks.

Technical Inspection – Level 2 (TA-2)

TA-2 comprehensively evaluates your machine’s critical systems to ensure peak performance and safety.

In addition to TA-1 tasks, we also perform:

- Safety Feature Verification: Inspection of safety systems to ensure compliance with lifecycle standards.

- Diagnostic Testing: Identification of fault codes and electronic system issues.

- Engine and System Analysis: Evaluation of engine performance, transmission, and pumps using SOS fluid samples and pressure readings.

- Component Examination: Detailed checks of implements, undercarriage, tires, tracks, and frame components.

- Performance Assessment: Measurement of cycle times, cylinder drift, and overall operational efficiency.

Schedule your TA inspections today!

These heavy equipment inspections follow a detailed and standardized checklist designed to cover every critical component of your equipment. This thorough approach ensures that no potential issue is overlooked, giving you confidence that your machinery is inspected with precision and care. From structural assessments to system diagnostics, our expert technicians leave nothing to chance, helping to maximize uptime and extend the life of your equipment.

Fill out the form below and a member of our team will get you scheduled.

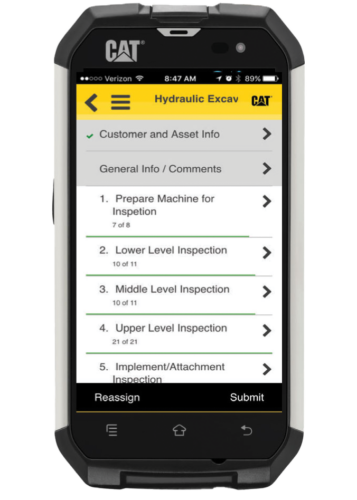

Want to Perform Your Own Inspections? Try Cat® Inspect!

Take control of your equipment maintenance with Cat® Inspect, the easy-to-use app with machine-specific checklists that lets you perform inspections yourself. Conduct thorough equipment checks, record findings, and generate detailed reports right from your mobile device. Stay proactive, reduce downtime, and keep your fleet running at its best—anytime, anywhere.

Stay ahead of equipment failure with proactive preventative maintenance before they turn into expensive repairs. Download the Cat® Inspect app today!

Learn More