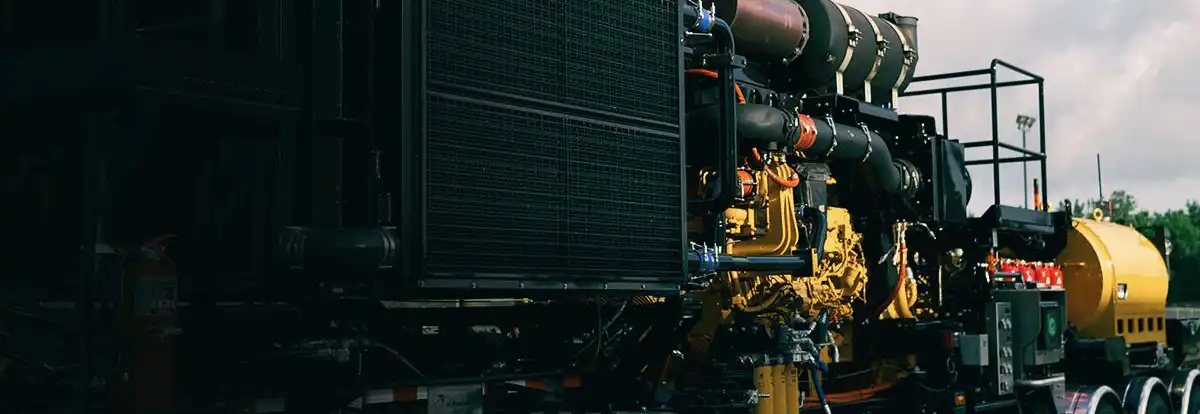

The land well service 3512E Dynamic Gas Blending™ dual fuel engine is certified to U.S. EPA Tier 4 Final emissions standard while offering the highest natural gas substitution in its class. The 3512E DGB will include factory solutions that emit approximately the same or less greenhouse gas (GHG) emissions as a comparable 3512E Tier 4 Final diesel engine. Additionally, the dual fuel performance of the new 3512E DGB has significantly increased compared to similar engines in its class with the ability to achieve 85% diesel displacement, further allowing for lower operating costs.

Maximum Rating 2500 BHP

Emissions U.S. EPA Tier 4 Final

Displacement 3596 in³

Minimum Rating 2250 BHP

Aspiration SCAC and ATAAC

Bore 6.7in

Displacement 3596in³

Flywheel Teeth 151

Flywheel and Flywheel Housing SAE No. 0

Governor and Protection Electronic (ADEM™ A5) / DGB System (ADEM™ A6)

Maximum Rating 2500BHP

Minimum Rating 2250BHP

Rotation from Flywheel End Counterclockwise

Stroke 8.5in

Emissions U.S. EPA Tier 4 Final

Height 107in

Length 137.4in

Weight 22657lb

Width 88in

Cooling System 52gal (US)

Lube Oil System - Refill 52gal (US)

Cat ADEM A6 DGB controls

Thermostats and housing, jacket and separate circuit water pump, gear-driven centrifugal

SCAC/ATAAC system

Dual DOC

Exhaust manifold, dry, bellows connection

Four turbochargers with watercooled bearings

Exhaust outlet, dual 10-inch ANSI round flange as part of aftertreatment

Flywheel, SAE No. 0, 151 teeth

Engine mounted Gas filter, water coalescing type

Clean fuel module boost pump

Fuel transfer pump

Common rail fuel system

Primary/secondary fuel filters

Fuel priming pump (electric)

Product LinkTM engine monitoring

Vibration damper and guard

Lifting eyes

Paint - Caterpillar yellow

Closed Crankcase ventillation - top mounted

Fumes disposal

Oil filter - RH spin-on type

Oil cooler

Oil filler and dipstick - LH

Oil scavenger pump

Oil pump

Oil pan drain valve, 1" NPT female connection

Trunion front support

Flywheel housing - two-sidedfailure options

Emergency stop logic inputs provided at 70-pin customer interface connection

ADEM A5 and A6 ECU system to provide customer programmable engine deration strategies to protect against adverse operating conditions

CEM/muffler support package Heavy-duty air cleaners (2 element with precleaners)

80, 95, or 150 amp charging alternator

Local speed throttle control

Throttle position sensors

Coolant conditioner

JW outlet coupling-style connections

JW inlet weld-flange connection

SCAC/ATAAC inlet and outlet coupling-style connections

JW inlet and outlet hose barb connections

SCAC/ATAAC inlet and outlet hose barb connections Water level switch gauge

JW Heater installation connections

Flex pipe kit

Residential mufflers (painted steel and stainless steel) with outlet elbow and rain cap

Allison and Twin Disc flywheel options

Product Link harness extensions

LAN adapters

Rear sump oil pan - 250-hour change interval

Front deep sump oil pan - 500-hour change interval

Front Crankshaft Adapter

Front crankshaft stub shaft

Accessory drive - upper RH

Hydraulic actuated air shutoff

Dual hydraulic starter - LH

Manual engine barring device

Hydraulic starter - LH

EIRS automatic start/stop system is available on factory orders as an attachment

Transmission oil cooler

Transmission oil cooler 2-1 connections

Torque converter connections

Air compressor